What Is Soft Robotics?

Soft robotics is an innovative field that builds robots using compliant materials—such as elastomers, silicone, and gels—instead of rigid metal and plastic. These soft robots mimic biological systems to achieve adaptability in shape and movement. It also helps reach safe human interaction due to compliant design and gentle handling of delicate or irregular objects.

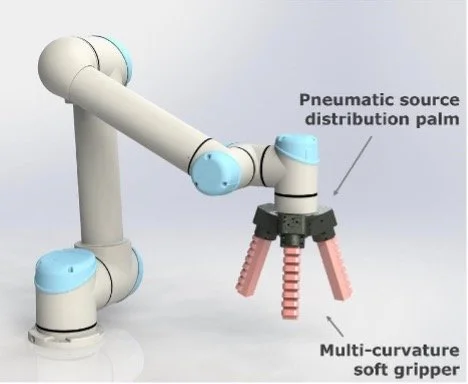

Source: ILC-driven control enhancement for integrated MIMO soft robotic system article at researchgate.net

Soft robotics relies on several core principles and technologies, including:

Pneumatic and hydraulic actuation: Inflating chambers within the robot cause bending, flexing, or contracting motions.

Electroactive polymers and shape-memory materials: These materials change shape when exposed to electrical or thermal stimuli.

Embedded soft sensors: Flexible conductive pathways monitor deformation, force, and position in real time.

Bio-inspired designs: Examples include octopus-like grippers and vine-like “soft-growing” robots that navigate confined spaces.

Soft robotics offers transformative solutions across diverse sectors:

Healthcare & Assisted Living

Minimally invasive surgical tools that navigate delicate anatomy safely

Exosuits and rehabilitation devices that assist movement by adapting to human motion

Food, Manufacturing & Agriculture

Soft grippers that automate handling of fragile items such as berries, eggs, or pharmaceuticals

Search & Rescue & Exploration

Shape-conforming robots that squeeze through rubble or underwater spaces inaccessible to rigid robots

Soft “growing” robots that extend into narrow conduits, ideal for inspections and surgical access

Environmental & Space Applications

Marine robots that minimize ecosystem disturbance

Lightweight, safe robots for confined space use in space habitats

Our research group applies fluid mechanics and soft matter theory to improve soft robotics performance. By analyzing how hydrogels, elastomers, and electroactive polymers deform under load and fluid pressure, we identify the best materials for durability and responsiveness. Using computational models—including continuum mechanics and multiphase fluid simulations—we predict how soft actuators bend and adapt, greatly reducing trial-and-error experimentation.

This highlights the clear advantages of soft robotics in adaptability, safety, and cost-effectiveness—proving its readiness for real-world applications.

However, the field still faces significant challenges:

Control complexity: Soft structures deform unpredictably, requiring advanced AI or evolutionary algorithms beyond traditional rigid-body models.

Material durability: Soft materials can degrade over time, especially under repeated stress or exposure to heat and chemicals.

Power and actuation: Dependence on bulky pumps limits portability; promising alternatives like dielectric elastomer actuators (DEAs) often require high voltages or generate low force.

Precision and load-bearing: Soft robots generally cannot handle heavy loads without supplemental support.

Manufacturing scalability: Custom molds and unique materials complicate mass production.

Sensing integration: Embedding reliable sensors without compromising flexibility remains a technical hurdle.

Addressing these challenges requires sustained, interdisciplinary research that combines advances in materials science, computational modeling, control systems, and manufacturing techniques. Continued innovation is crucial to develop softer, more durable materials, more efficient and compact actuation methods, and smarter control algorithms capable of handling the complexity of soft structures.

By pushing the boundaries of what soft robotics can achieve, ongoing research can unlock new applications and accelerate the translation of these technologies from the lab to everyday use—ultimately making soft robotics more practical, accessible, and impactful across medicine, industry, and beyond.